1 内容介绍

油气井流入动态是确定油气井合理工作制度及动态分析的基础,对于溶解气驱油藏,油气井流入动态呈非线性,目前常用IPR曲线计算压力与产量的关系.

2 部分代码

% function [Psum,h,V_gas,detap,P]=boreholepressure(Q_liquid)

clc

clear all

close all

Q_liquid=5;

%%%------------------------基础参数-----------------------------

p_stand=0.101325;

T_stand=273.15; %热力学温度

density_gas_stand=1.25/1000;

V_stand=0.022414;

T0=293;

Gt=2.84;

%%%%———————————————井身结构———————————————

H=43860;

H_1=1850 %%开始造斜

H_2=2634 %造斜结束

d_bore =244.5; %%技术套管

d_piple=127;

d_bore_1=215.9;%%三开井眼直径

d_collar=127; %177.8mm

L_collar=150;

%-----------------------钻井参数--------------------------------------

Q_liquid=25;

Q_gas=111;

visocity_liquid=40; %%mpa s

visocity_gas=25;

Yp=8; %pa

density_mud=1.48;

deta_H=5;

N=H/deta_H;

Tg=zeros(N+1,1);

%------------------注气量----------------

Ratio_gas=Q_gas/Q_liquid;

p_gas=zeros(N+1,1);V_gas=zeros(N+1,1);;density_mix=zeros(N+1,1);

visocity_mix=zeros(N+1,1);Q_mix=zeros(N+1,1);detap=zeros(N+1,1);

v=zeros(N+1,1);Re=zeros(N+1,1);h=zeros(N,1);

%----------------------生产井眼温度和静液柱压力剖面----------------------------------

for i =1:N+1

if i>1 && i<=H_1/deta_H+1

Tg(i,1)=T0+(i-1)*deta_H*Gt/100;

p_gas(i,1)=(i-1)*deta_H*9.8*density_mud/1000; %%单位兆帕MPa

elseif i>H_1/deta_H+1 && i<=H_2/deta_H+1

Tg(i,1)=Tg(H_1/deta_H+1,1)+39.2*(i-(H_1/deta_H+1))*Gt/100;

p_gas(i,1)=9.8*density_mud/1000*H_1+12.7*(i-(H_1/deta_H+1))*9.8*density_mud/1000; %%单位兆帕MPa

V_gas(i,1)=1/(1+p_gas(i,1)*T_stand/(Ratio_gas/p_stand/Tg(i,1)));

elseif i>H_2/deta_H+1 && i<=N+1

Tg(i,1)=T0+(H_1+636)*Gt/100;

p_gas(i,1)=(H_1+636)*9.8*density_mud/1000; %%单位兆帕MPa

end

end

%---------------------计算气体浓度和混合物密度---------------------------

for i=1:N+1

V_gas(i,1)=1/(1+p_gas(i,1)*T_stand/(Ratio_gas*p_stand*Tg(i,1)));

density_mix(i,1)=density_mud*(1-V_gas(i,1))+V_gas(i,1)*density_gas_stand*p_gas(i,1)*T_stand/Tg(i,1)/p_stand;

end

%---------------------计算混合物粘度及混合物粘度---------------------------------------

for i=1:N+1

if V_gas(i,1)>0 && V_gas(i,1)<=0.54

visocity_mix(i,1)=visocity_liquid*(1+3.6*V_gas(i,1));

elseif V_gas(i,1)>0.54 && V_gas(i,1)<=0.96

visocity_mix(i,1)=visocity_liquid/(1-V_gas(i,1)^0.49);

else

visocity_mix(i,1)=visocity_gas*(1+2.5*(1-V_gas(i,1)));

end

Q_mix(i,1)=(1+Ratio_gas*p_stand*Tg(i,1)/T_stand/p_gas(i,1))*Q_liquid;

end

%-------------------------计算环空返速与雷诺数--------------------------

P=zeros(N,1);

for i=2:N

P(i,1)=sum(detap(2:i));

end

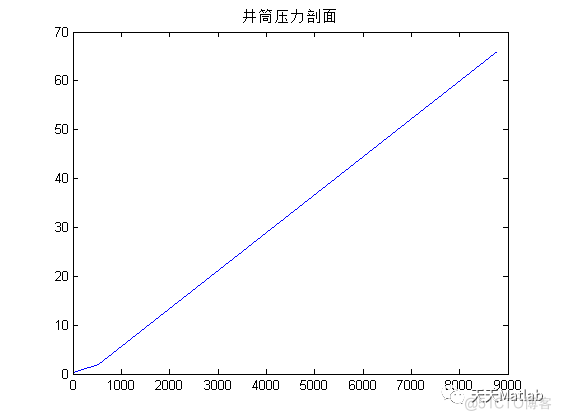

figure(2)

plot(P)

title('井筒压力剖面')

3 运行结果